Custom Wheel Designs

Designing custom automotive rims is not only an artistic challenge but also a precise engineering exercise. Using Autodesk Inventor, designers can bring concept ideas to life with high fidelity, combining reference photography with advanced modeling tools. This article demonstrates the process of creating accurate, aesthetically refined rim designs using Inventor, focusing on both Mercedes’ Organic Rim Design and BMW’s 666M Sport Alloy Wheel as modeling studies.

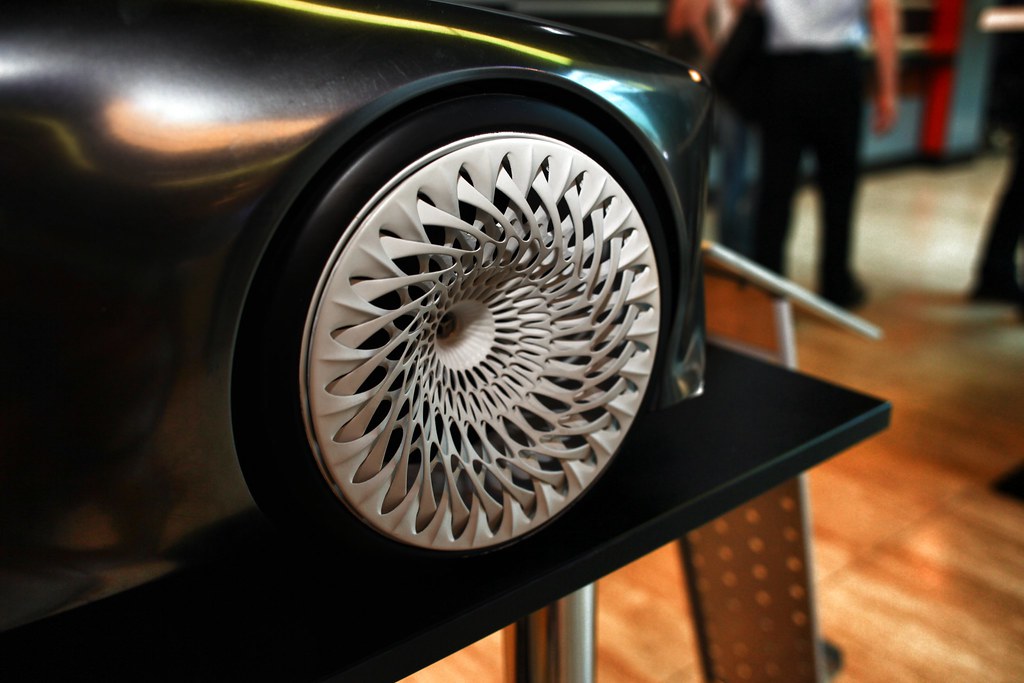

This reference image showcases the Mercedes Organic Rim Design, a concept that blends fluid geometry with mechanical precision. In Autodesk Inventor, such a design can be approached using surface modeling techniques to replicate the flowing contours of the spokes. The organic structure seen here requires lofted and swept surfaces to achieve its smooth transitions, ensuring that the rim remains both visually dynamic and aerodynamically optimized.

In this Inventor-rendered model, the emphasis is on translating the natural inspiration of the original design into a manufacturable 3D form. The intricate leaf-like patterns were created using pattern features and adaptive sketches that respond to the rim’s curvature. The goal is to maintain structural balance while minimizing material thickness, showcasing Inventor’s ability to handle complex symmetry and parametric refinement with ease.

This photograph of the BMW 666M wheel serves as a precise visual and dimensional reference for modeling. The sharp lines and angular spoke geometry contrast with the Mercedes design, demanding a more mechanical and performance-oriented approach in Inventor. Careful observation of lighting and curvature helps define the chamfers, bevels, and subtle depth variations that give the wheel its aggressive stance and modern identity.

The Inventor model captures the spirit of BMW’s engineering precision. Using revolve, extrude, and mirror features, the rim’s geometry is built layer by layer, with emphasis on parametric constraints for dimensional consistency. The fine detailing on the hub and spoke intersections was refined through filleting and surface smoothing, ensuring both structural integrity and visual realism. This model highlights how Autodesk Inventor empowers designers to merge artistry with accuracy.

Modeling custom rims in Autodesk Inventor transforms design references into tangible, detailed 3D assets ready for visualization, rendering, or even prototyping. Whether drawing inspiration from organic or performance-driven aesthetics, the process enhances both technical understanding and creative exploration. Each rim becomes not only a statement of design skill but also a testament to the power of digital craftsmanship in modern automotive design.

No Comments